ABOUT US

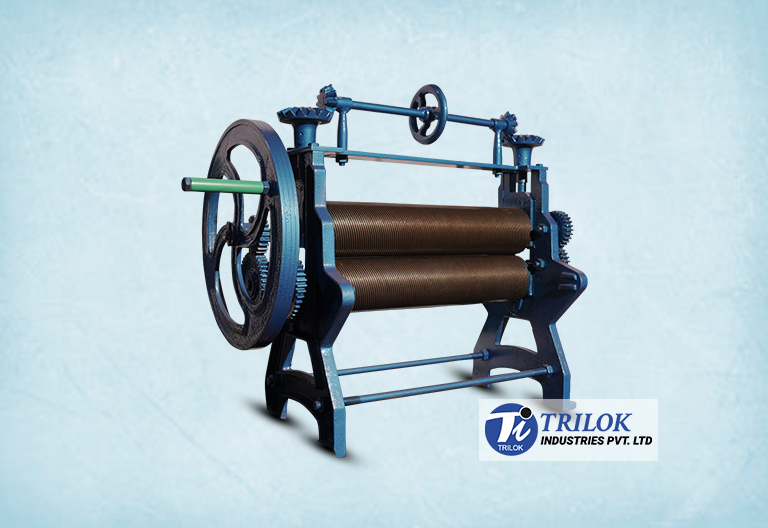

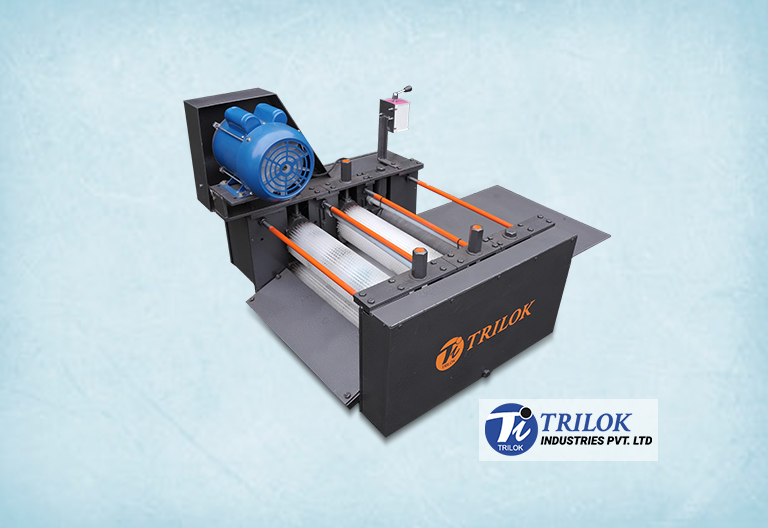

Trilok Industries Pvt Ltd rubber sheet machineries are sold in all major rubber growing states in India. The raw materials used to manufacture our rubber rollers are subjected to strict quality control checks. With very minimal routine maintenance, our rubber rollers will keep working for years. The design is so robust and rigid, thereby eliminating the use of foundation bolts. We provide excellent service and support both online and offline.

Trilok Industries was founded by a dedicated and outstanding team of 3 entrepreneurs who have extensive experience in manufacturing rubber products. Our goal is to provide innovative and quality products with very little maintenance.

Trilok Industries is always determined to offer its clients better quality and standard machines and continuously update manufacturing systems and have a highly skilled and trained workforce.

Our company has gained recognition as the manufacturer and supplier of rubber sheet making machines not only in Kerala but also in Tamil Nadu, Karnataka, Andhra Pradesh, Odisha, and the northeastern states of India, and we have a large clientele all over India. We also export machines to African countries like Ghana, Congo, and Botswana.

Our team of experts is proficient in developing the machine in a standard suitable for the client’s requirements, thereby increasing the productivity and income of the end-user.

Our Service and Support

Service wins the game. We pledge ourselves and our work to complete customer satisfaction. Our technical interest has led us to adopt new technologies and empowered us to emerge into the forefront, creating a brand for our products.